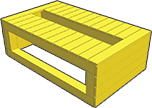

Patio Table

Plant Trough Hack

A patio table adds sophistication and charm to any outdoor space. It anchors the seating elements and provides a surface for food, drinks, and plants. Designed with simplicity and elegance in mind, this table features a strong, sleek base with cladding that waterfalls from the top down two sides.

Using 4x4s as legs, 2x4s for structure, and 1x4s for cladding, this project takes shape in just a few simple steps. When the leg assemblies are completed, the support structure is secured to create the table's skeleton. From there, it's just a matter of attaching the slats that waterfall over three faces.

After a light sanding and a waterproof finish is applied, you and your family will be set to enjoy some R&R.

Before you get started, please read our info on safety, fasteners and building tips.

Before building, please consult our Terms of Use.

Materials

- (2) 4 x 4 x 10' YellaWood® brand pressure treated pine

- (3) 2 x 4 x 10' YellaWood® brand pressure treated pine

- (7) 1 x 4 x 10' YellaWood® brand pressure treated pine

- (1) ½ lb box 2½" wood screws + appropriate bit

- (1) box (approx. 50 screws) 4" heavy-duty lag wood screws with 5/16" head

- Preferred wood finish

- YellaWood Protector® Stain and Sealer

Tools

- Pencil

- Measuring tape

- Miter saw

- Table saw

- Drill/driver

- 3/16" drill bit

- 1/2" Forstner bit

- 5/16" Hex driver bit

- Clamps (12" and 4')

- Framing/combination squares

- Combination countersink drill bit (with 2" long 1 /8" bit)

- Radial sander

- Damp rag to wipe up excess glue

- Waterproof wood glue

Cut List

- A. (4) 4 x 4 x 47"

- B. (4) 4 x 4 x 8 ¾"

- C. (2) 2 x 4 x 23 ½"

- D. (4) 2 x 4 x 44 ¼"

- E. (21) 1 x 4 x 30"

Plant Trough Hack

Hack Materials

- (1) 1 x 4 x 12' YellaWood® brand pressure treated pine

- (1) 2 x 4 spacer jig (used in Step 11)

- (1) ½ lb box 2 ½" wood screws

- Preferred wood finish

Hack Tools

- Pencil

- Measuring tape

- Miter saw

- Combination countersink drill bit

- Drill/driver

- Radial sander

- Damp rag to wipe up excess glue

- Waterproof wood glue